Shedding a Light on Solar Energy

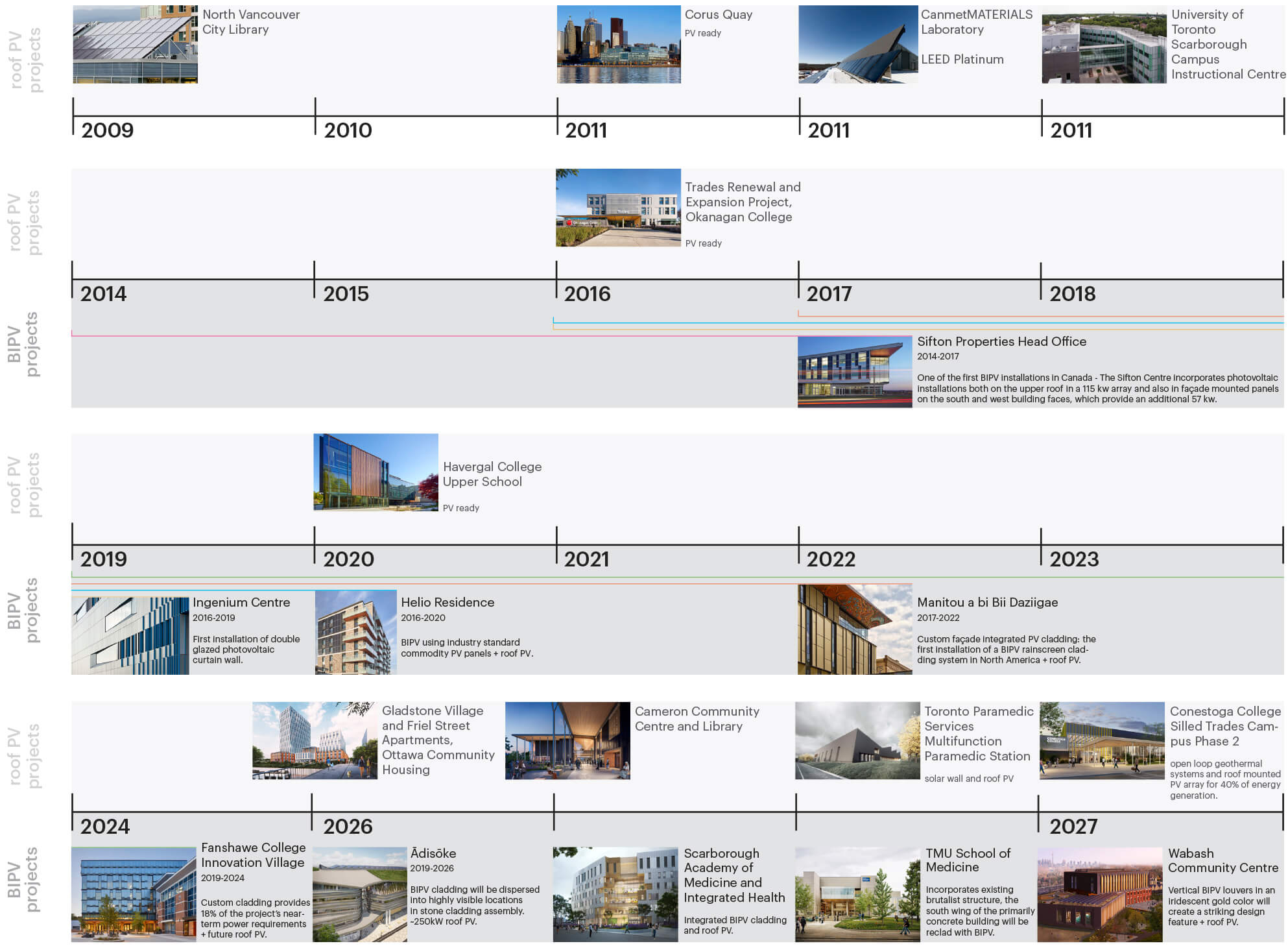

At Diamond Schmitt, we are committed to designing buildings that give back more than they take, shaping a more sustainable future through innovation. For over 15 years, we’ve been integrating renewable energy, designing solar-ready buildings and pioneering the use of photovoltaic systems long before this became standard practice. Today, we continue to push boundaries, exploring new ways to harness renewable energy across sectors to create healthier, more resilient communities and a thriving planet.

Over the past decade, solar technology has come a long way – from the early days of utilizing industry standard commodity solar panel applications to the development of customized building integrated photovoltaic (BIPV) cladding – creating a remarkable opportunity to re-think the building envelope and opening the possibilities of generating on-site renewable energy through the buildings that we design.

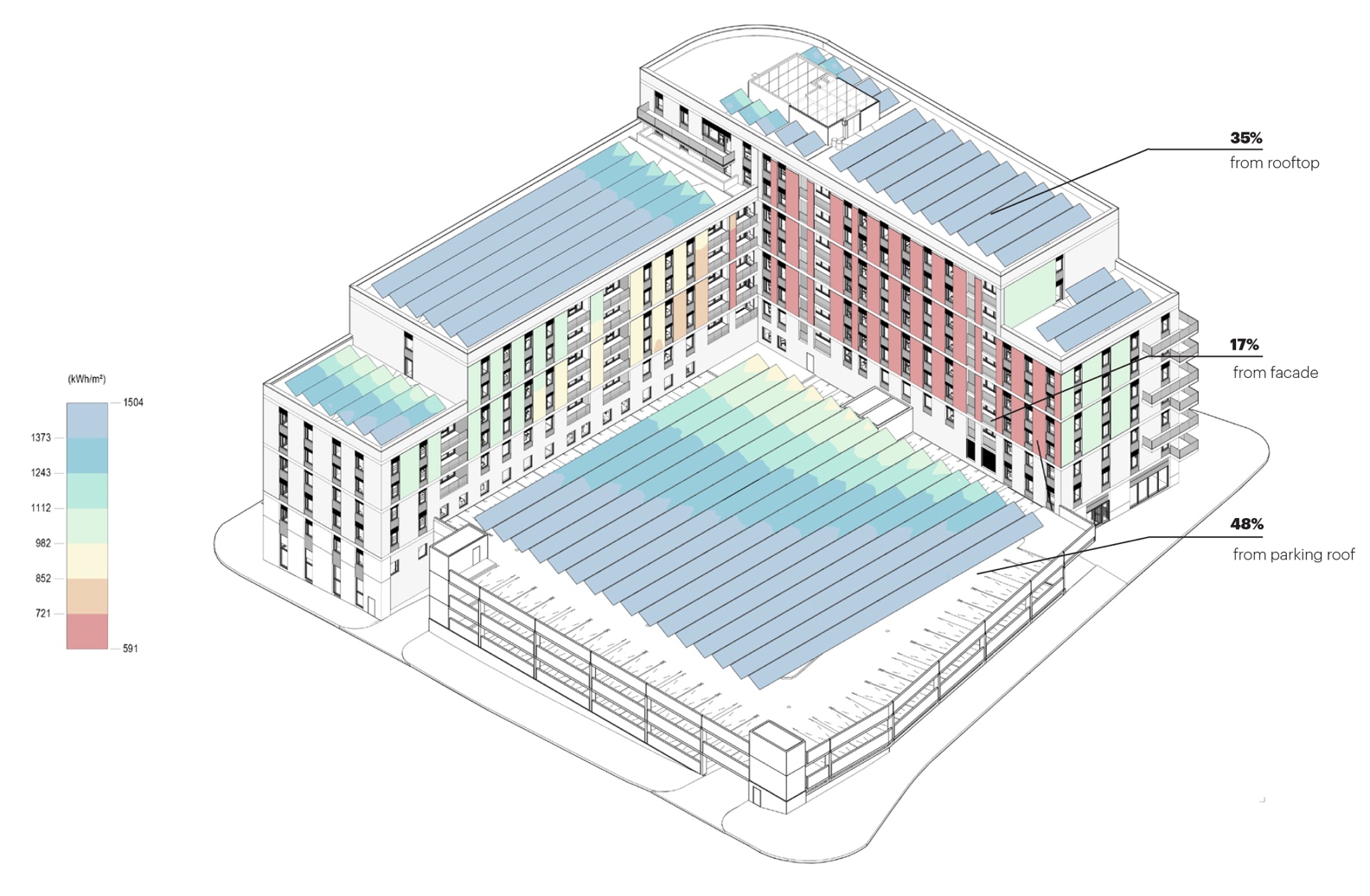

Façade-integrated photovoltaics is a valuable strategy for energy production; when incorporated along with rooftop PV, the overall potential output can be considerably higher, as the coverage on a building is substantially increased. Custom BIPV façades create a distinct profile, can be used on building types of all scales, and they facilitate energy autonomy while being a necessary building element. Depending on context, all façades of the building, even the most northerly-facing can receive enough sunlight to generate electricity, demonstrating viable ROI.

Adopting Building Integrated Photovoltaic (BIPV) Systems

The following projects are illustrative of these explorations and a growing body of expertise within our firm – and additionally, more importantly, the development of knowledge and experience within the communities where these projects are built. Employing building integrated photovoltaics in these projects has helped advance understanding within the construction sector, authorities having jurisdiction (AHJ), among our clients and the broader public, of the potential of PV as a viable energy source.

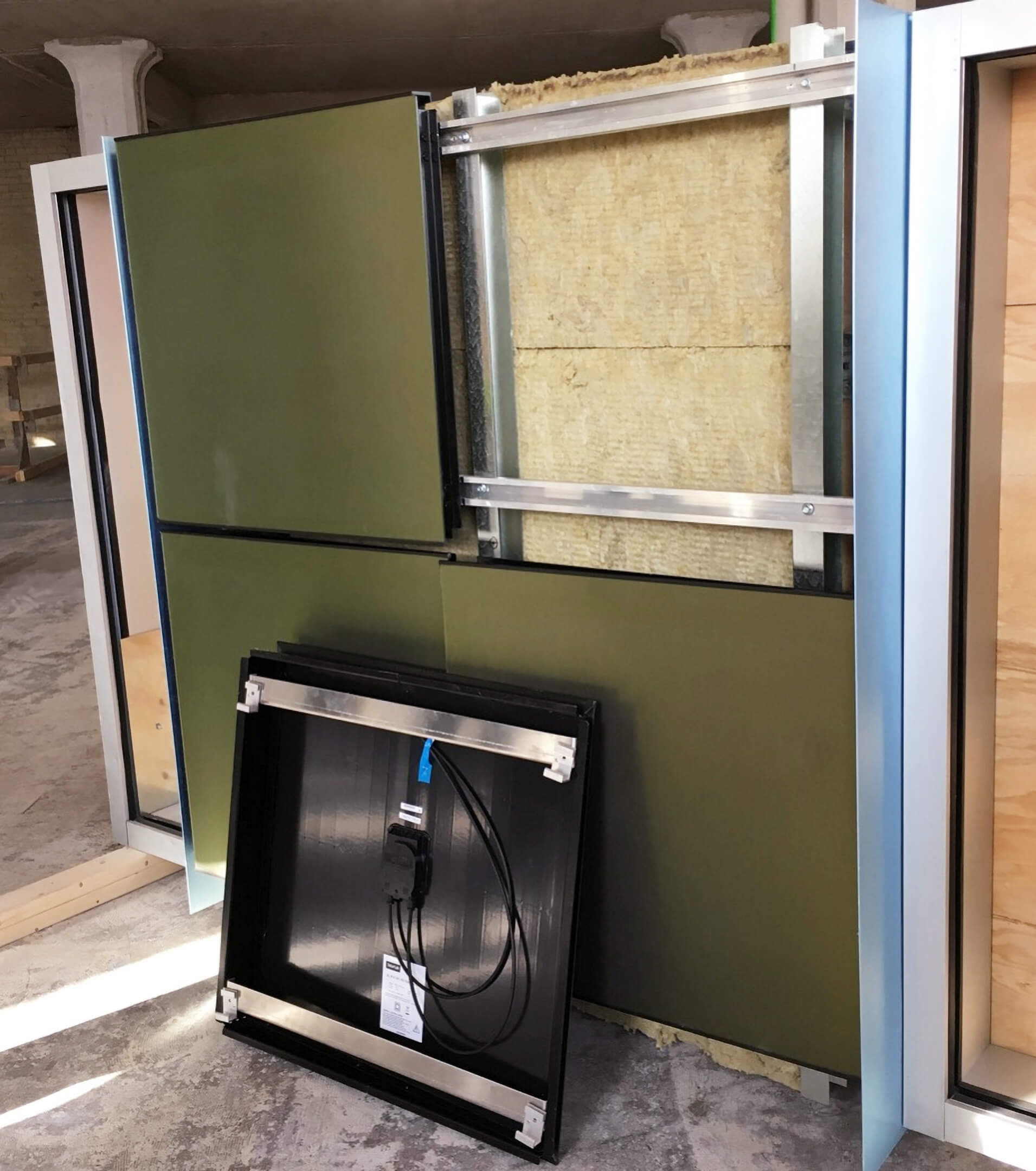

In each case, the lessons we have learned involve multiple project partners. Fully integrating components of the building envelope and building power systems has required an exceptional degree of collaboration with solar façade specialist fabricators, project construction trades and consulting disciplines. Investigating cladding precedents, analogous conditions found in rooftop PV arrays, the development of new components to suit Canadian climate conditions and AHJ regulatory requirements has been part of this learning process. We have found that authorities, alongside local construction trades, are typically encountering this cladding approach for the first time, and creating mock-ups has allowed for early understanding and willingness to support BIPV projects.

Breaking Ground with Sifton Properties Head Office and Helio Residence

Our experimentation with photovoltaics beyond roof PV installations began with Sifton Properties Head Office (2017) in London, Ontario. The mixed-use development was the first building completed for the city’s West Five community, with the ambitious aim of achieving net zero energy use on a neighbourhood scale, including 450,000 sq ft of commercial space, a central park, and 2,000 households comprising of apartments, townhouses, retirement residences, and high-rise buildings.

The Sifton Centre features a solar rooftop and a façade of standard PV panels, which generates sufficient electricity to power 14 houses for a year.

Following the completion of Sifton Centre, we continued work within the West Five community on the construction of the Helio Residence (2020). Similar to Sifton Centre, the 10-floor building comprised of 115 residential rental apartments represents a significant step towards the net zero development’s reduction in overall energy use, generating a projected 50% of its energy requirements from BIPV panels on its roofs and walls.

Without including the solar array input, Helio’s Energy Use Intensity (EUI) from energy and thermal efficiency alone comes to 91 kWh/m2/yr, class-leading for this building typology where the national average exceeds 200kWh/m2/yr. With projected solar production factored in, this brings the EUI down to ~40 kWh/m2/yr.

Both the Head Office and Helio Residence were developed using industry standard commodity PV panels. The Head Office used applied panels over insulated metal sandwich panel cladding, while Helio used PV as the outer layer of a conventional insulated rain-screen cavity-wall construction. Challenges included working with fixed dimensions and developing cladding flashing and closure details to create a distinctive envelope from standardized modular components.

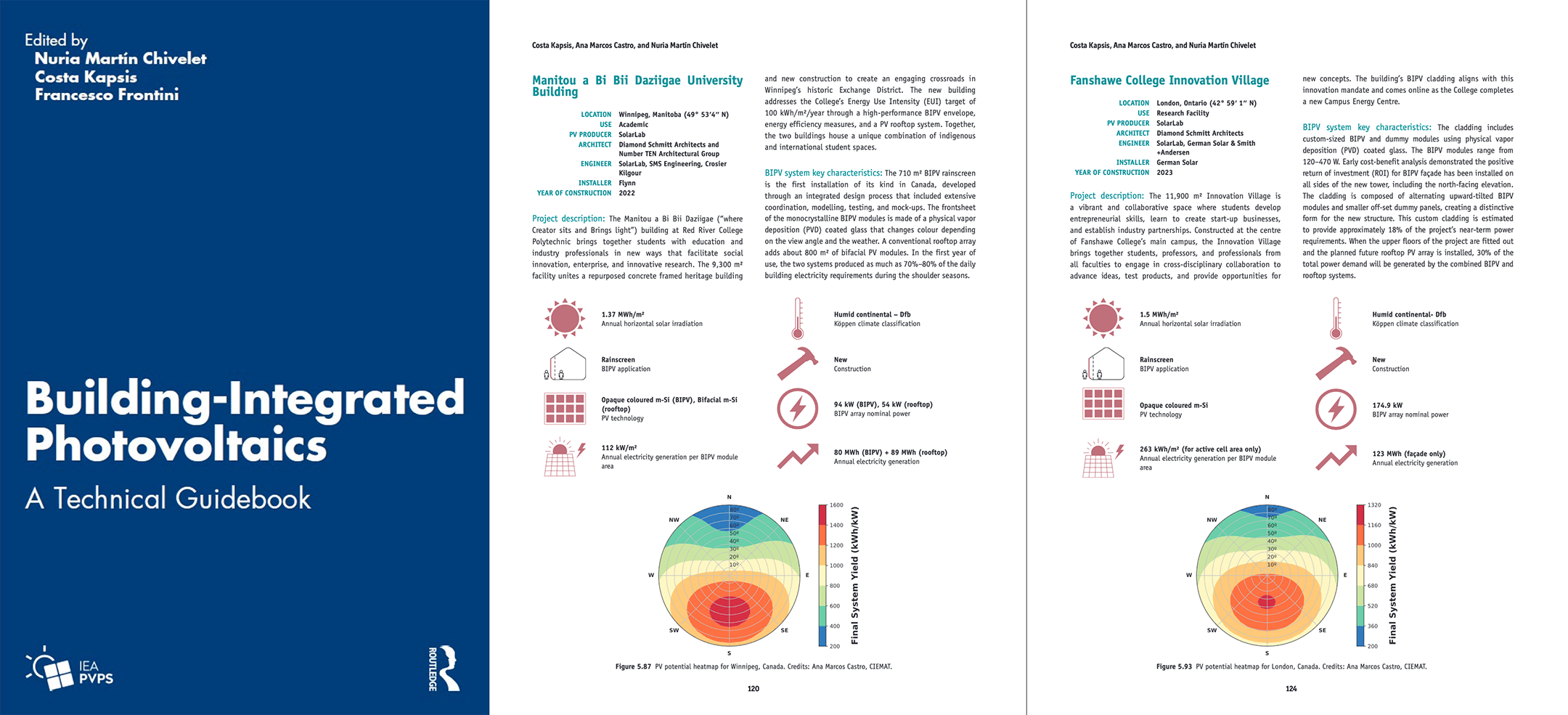

Pioneering the use of a BIPV rainscreen cladding system at Manitou a bi Bii Daziigae

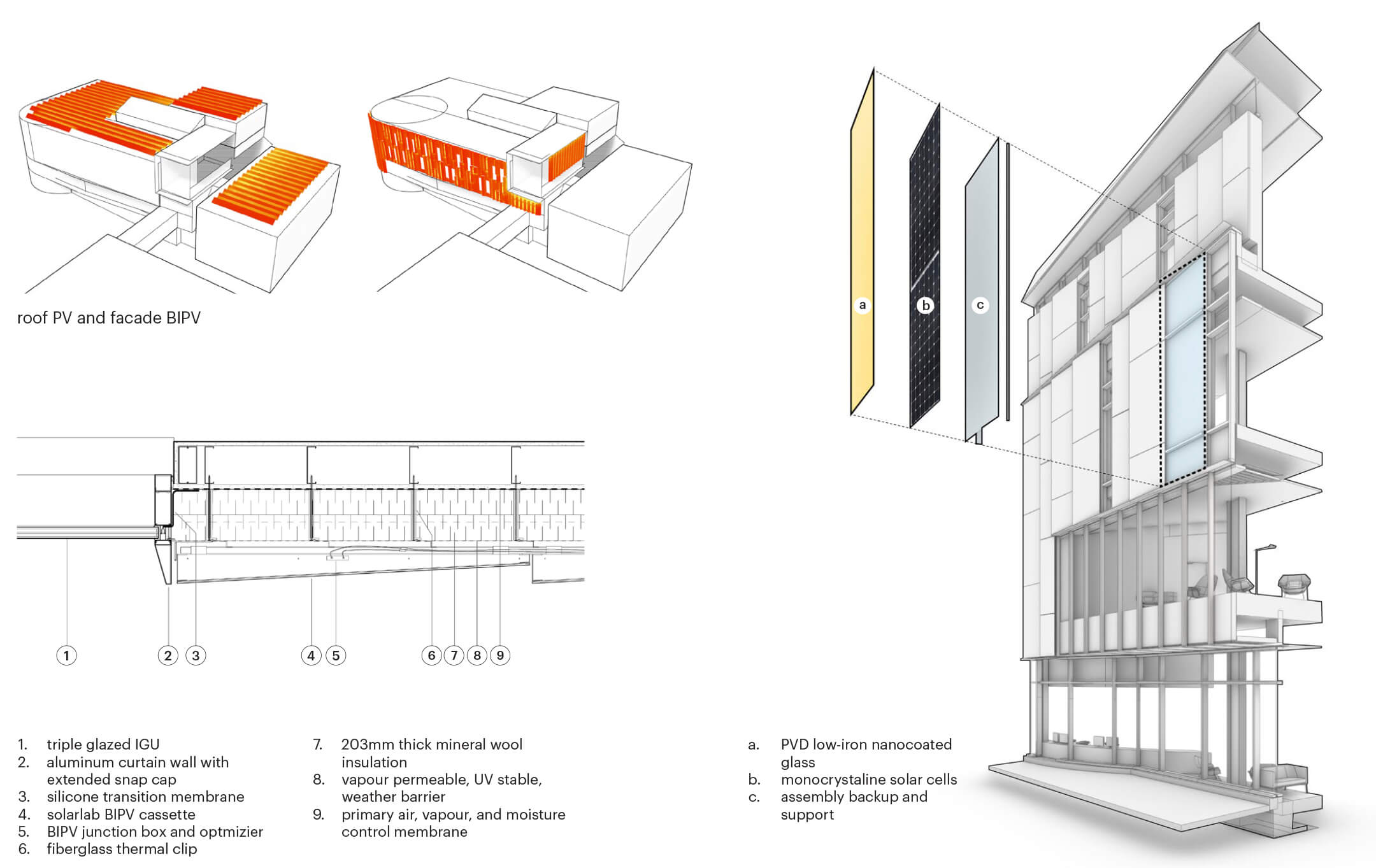

Manitou a bi Bii Daziigae (2021) at RRC Polytech was the first site where we employed a complete façade-integrated PV cladding system. Developed through an integrated design process, realizing the project involved extensive coordination, modelling, testing, and mock-ups.

Uniting a repurposed concrete framed heritage building and new construction, the 100,000 sf facility creates an engaging crossroads in Winnipeg’s historic Exchange District. The historic Scott Fruit Building retains key heritage elements, transformed to achieve a new standard for energy efficiency and effective use, while the façade of the new building is made of dynamic PVD coated panels that generate energy and change colour depending on the angle of view and the weather.

BIPV construction was a new approach for the local building department, so a physical mock-up was constructed early in the design process so that city staff could see the system firsthand, ask questions, and be well prepared when it came time to issue permits and carry out inspections. The building department subsequently developed their own on-line advisory notice to help other future project owners understand the pathway to constructing these systems.

Initial modelling predicted that the combined façade and roof-top PV systems would provide approximately 18% of the building’s overall energy requirements. In its first year of use, the combined PV systems provided as much as 70-80% of the daily base building power requirement in shoulder seasons, as measured through BAS power metering.

Manitou a bi Bii daziigae creates a Canadian first: a beautifully integrated custom rain-screen photovoltaic wall that creates energy, and animates the building.

Setting a New Standard at Fanshawe College

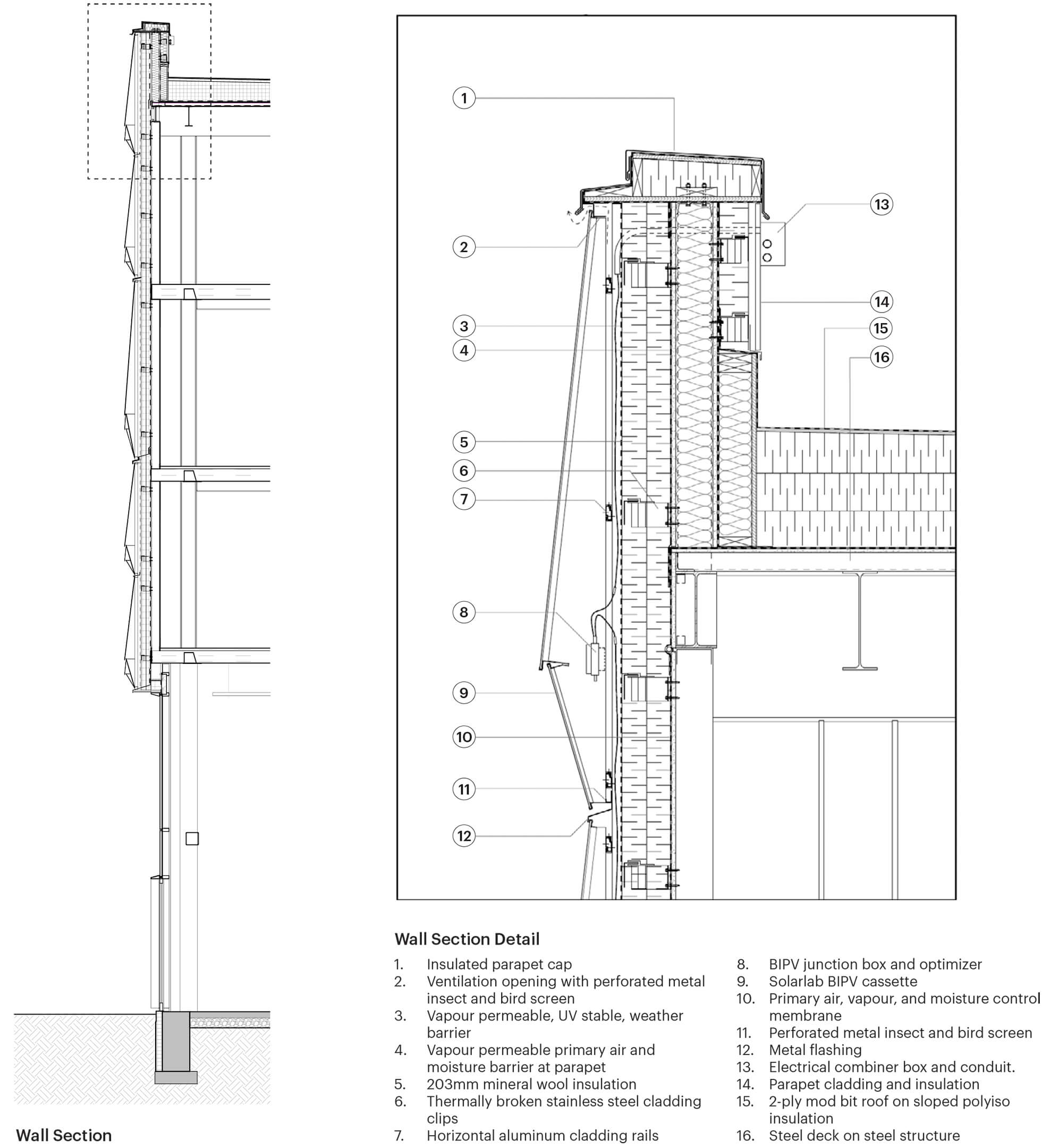

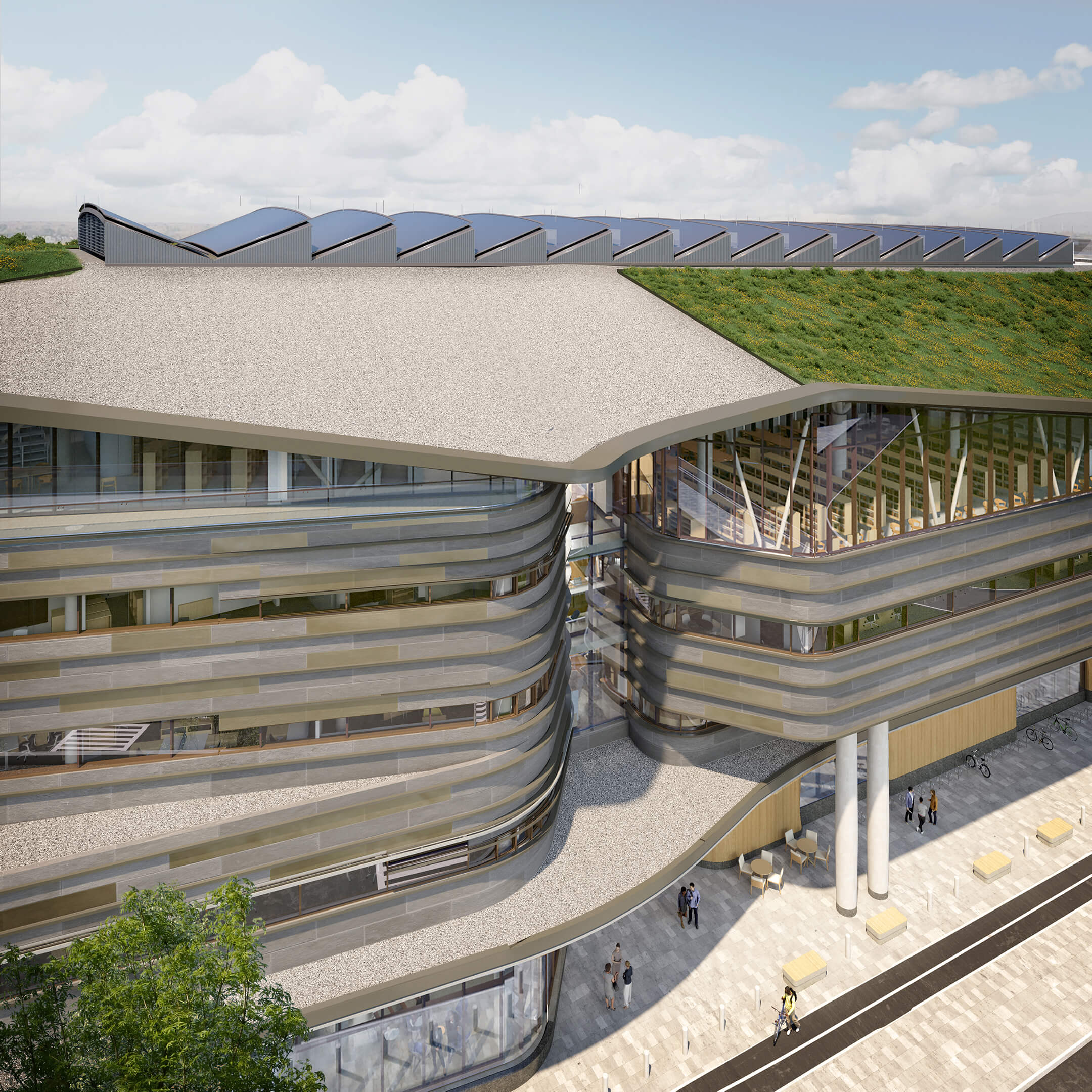

At the Fanshawe College Innovation Village (2024) we took our work in BIPV technology to the next level with a photovoltaic cladding system that wraps all façades of the new facility.

Designed as a vibrant and collaborative space, the 126,828 sf Innovation Village is a place where students develop entrepreneurial skills, learn to create start-up businesses, and establish industry partnerships. Constructed at the centre of Fanshawe College’s main campus, the Innovation Village brings together previously disconnected spaces to create a new heart for the College. The building’s custom BIPV cladding aligns with the College’s innovation mandate, demonstrating energy efficiency, resilience and forward-thinking.

Custom-sized active and passive panels of coated low-iron glass, with active PV panels ranging from 120W-470W per panel, clad the Innovation Village. Early cost-benefit analysis demonstrated the positive ROI for BIPV with the solar façade installed on all sides of the new tower, including the north-facing elevation. Composed of alternating upward-tilted active panels and smaller off-set passive panels, the cladding creates a distinctive form for the new structure. When the upper floors of the project are fitted out and the planned future rooftop PV array installed, 30% of the total power demand will be generated by the combined PV systems.

The sub-trade contractors responsible for the installation of both PV systems are also responsible for constructing the associated back-up wall cladding components (AVB, insulation, thermal clips/girts/sub-framing, weather barrier and fire-blocking). Detailed mock-ups were constructed on-site at intervals to study and test the fit and alignment of components. As the BIPV cladding panels were fabricated outside of Canada, testing of the component parts included off-shore and on-site testing and labelling to meet Canadian regulatory standards.

Shedding a light on the future

As we continue to explore the potential of these leading solar technologies, additional projects are underway.

Ādisōke (2027), the new Ottawa Public Library – Library and Archives Canada joint facility, is set to feature BIPV cladding strategicallyplaced in prominent areas within the building’s stone cladding assembly. In addition, a 250 kW rooftop photovoltaic (PV) system will be installed, enhancing the building’s energy efficiency and showcasing the potential of this technology. Given initial net zero carbon standards typically targeting office and residential buildings, we collaborated with the Canada Green Building Council (CaGBC) to model energy requirements and performance opportunities for this unique building type, in the process contributing to the evolution of these standards. Setting a precedent for future large-scale public developments of this kind, where absolute targets are replaced with more nuanced project-specific considerations, the design of Ādisōke demonstrates how our role as architects has influence on evolving building energy guidelines from a regulatory perspective.

The Myron and Berna Garron Health Sciences Complex at the University of Toronto – Scarborough Campus (2026) will incorporate both integrated PV cladding and rooftop PV systems. These multi-layered panels will generate energy while positively contributing to the building’s appearance, with three different tones arranged to emphasize the opening of the design’s central atrium. Inclusion of this technology, in tandem with standard photovoltaics on the roof, will contribute a significant amount of renewable energy towards the building’s operation.

While most projects employing BIPV are new construction, we also recognize the potential BIPV holds for deep energy retrofits of existing structures – with both types pursuing a mandate to demonstrate ambitious targets for energy efficiency, low carbon emissions and resiliency. Toronto Metropolitan University’s new School of Medicine (2025) transforms the former Bramalea Civic Centre into a state-of-the-art medical school that will be home to aspiring medical students, and act as a welcoming bridge to the community. With the ambition of reducing energy and greenhouse gas emissions, the south wing of the Brutalist building will be reclad with BIPV.

Developing and advancing Canadian Standards for BIPV

Diamond Schmitt has been an active participant in the CSA technical sub-committee tasked with developing Canadian versions of the international standards for BIPV modules and systems. This participation in an evolving PV industry is integrally linked with the development of local construction and AHJ expertise, expanded incrementally through each project. In parallel we are encouraged to see increasing willingness among our clients in private and public sectors to consider BIPV, or to plan for future installation of PV systems, and we continue to share knowledge and expertise gained through this decade of exploration.

We are often invited to speak at conferences to share insights on the potential of BIPV; discuss advancements in PV technology on projects complete and underway; outline how BIPV design strategies differ depending on building type and context; and share lessons learned, advancing the construction industry’s understanding of photovoltaics as a viable and beautiful renewable source of energy on future projects. We are contributors to the recently published IEA PVPS international BIPV Guidebook, with two of the five North American examples coming from our portfolio.

Underlying each of these projects is the fundamental requirement to produce energy effectively on-site. Energy modelling and studies have demonstrated the contributions from BIPV to overall building energy use, with increasing value demonstrated as we learn from project to project. Risk and exploration are balanced with research, testing, mock-ups and regulatory review. Collaboration among multiple project partners – trades, consultants, systems fabricators and owners – is essential to this work. This has created an environment of confidence and trust which is essential for our clients, and certainly part of what fuels our own team’s work as we continue to look for ways to evolve this technology.

In each instance the incorporation of BIPV systems has been integral to an approach to design excellence. The work is highly informed by context, in terms of the physical setting of each project, but additionally through exploration of what has been possible with given trades, local regulatory conditions, and evolving system components. What began as experimentation with industry standard commodity PV components has steadily shifted to more customized, fully integrated building envelope installations at different scales. Innovation leads to continued opportunities, better understanding and increasingly functional and site-specific results.

Diamond Schmitt have been named to Fast Company’s prestigious list of the World’s Most Innovative Architecture Companies of 2025, earning the ninth spot in the Architecture category for our pioneering work with customized building integrated photovoltaic (BIPV) cladding.